MDE/ BDE with ProVis

ProVis means "Production Visualization" and is a modern MDE/BDE system with graphical user interface, based on modern database technology and client-server architecture.

ProVis offers:

- Reduction of lead times and delivery times

- Optimization of capacity and resource utilization

- Increase productivity

- Transparency in production control

- Accompanying calculations

- Automatic post calculation

- Process control through key figures such as OEE* , GAE*, cp and cpk*.

- Recording of all relevant process data

- Quantity recording even without terminal

- Sensors and industrial PCs for machine and process data acquisition

- Umfangreiche Schnittstellen zu allen Maschinensteuerungen

(OPC, OPC-UA, MT-Connect, Euromap, Focas, Heidenhain) - More than just quantity takeoff

* GAE Gesamtanlageneffektivität ist ein Maß für die Wertschöpfung einer Anlage,

* Cp und CpK sind Kennzahlen zur statistischen Bewertung eines Prozesses

Production data acquisition

The new PDA client with modern ergonomic user guidance for touch screens is a completely new development under .net and will replace the previous proven "WINMDEPC". It can be used as MDE client or BDE client.

As a MDE client, machine statuses are monitored, piece counts are recorded, personnel and warehouse bookings are made, CNC programs are transferred, measuring tasks are carried out and much more.

Work instructions assigned to the production order can be displayed in the form of videos.

All components of a parts list are displayed graphically.

The modern touch interface makes it child's play to navigate through the graphical tree structure of a parts list.

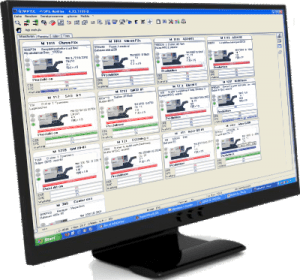

Der ProVis Monitor zeigt die aktuellen Zustände und Stückzahlen der jeweiligen Maschine an.

Im Laufzeitdiagramm werden alle Ereignisse auf der Zeitachse grafisch angezeigt.

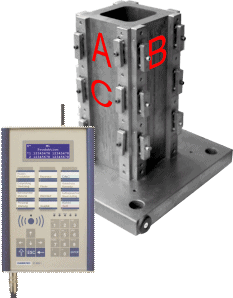

Pallet processing

On machining centers, several different articles A, B, and C are produced for different production orders in different batch sizes in one setup and on one pallet. The time for machining the entire pallet is provided by the machine via a clock signal.

With the pallet module ProVis is able to manage and process several different articles to different production orders. ProVis distributes the total processing time to the individual production orders according to a predefined distribution key.

Energy management

ProVis energy monitoring records and visualizes the energy consumption of your production resources. Via the IC901, the consumptions are reported directly to the control station. The consumption values are archived and visualized in the same way as the process data.

The energy consumptions recorded in this way can later be assigned to machines, shifts, tools, materials and articles. The energy consumption per production order is required for subsequent recalculation.

ProVis process indicators and process traffic light

The ProVis MDE/BDE system and the new MDE/BDE terminal IC901 create transparency in production.

Always knowing at a glance what is going on in production or what is not going on as it should - this is made possible by the new IC901 industrial PC in conjunction with the process traffic light and corresponding software.

The process traffic light indicates the current status of machine tools in traffic light colors on the basis of relevant key figures. For example, the overall equipment effectiveness (OEE) indicator provides information on the degree of utilization, performance and quality rate of the respective machine.

PPS Schnittstellen (zu allen gängigen PPS-Systemen)

GEWATEC offers interfaces to all common PPS systems.

Zu folgenden PPS-Systemen sind bereits Schnittstellen realisiert:

ABAS, Agilisys, Apollo, Axapta, Bäurer, Brain,GPPS, IFAX, Infor, INFRA, Navision, SAP/R3, SAP Business one, Semiramis uvm.