Energy management with ProVis

Current developments in climate policy require changes in the way energy and resources are handled. Through legal regulations and government subsidies, companies are required to take appropriate measures to curb energy waste and reduce energy consumption. The German government's Energy Tax Act (EnergieStG) sets new standards in dealing with energy. This law stipulates tax relief on the EEG levy and on energy and electricity. Companies are required to introduce an energy management system in accordance with DIN EN ISO 50001.

The recording of energy consumption naturally uses the existing infrastructure of ProVis MDE data acquisition. All sensors of ProVis-NT are able to record energy consumption, archive it and provide the data for evaluation with modern BI tools. Thus, ProVis supports the monitoring and reduction of energy consumption.

GEWATEC Energy Management is registered with the Federal Office of Economics and Export Control (www.bafa.de) as an eligible software.

Din 50001

The aim of ISO 50001 is to support the structureof systems and processes

- Improving energy use Type and method of using energy

Examples: Ventilation, lighting, heating, cooling, transportation, production lines. - Reduction of energy consumption and the amount of energy used

- Improving energy efficiency Ratio between an achieved output and the energy used

Energy management according to ISO 50001

ISO 50001 describes a globally applicable standard that is intended to support organizations in establishing systematic energy management. It was published by the International Organization for Standardization (ISO) in June 2011 and became effective on April 24 2012

in Germany. In addition to energy data management and the implementation of individual technical measures, systematic energy management primarily involves strategic and organizational management approaches. Conditions are created to consciously control energy consumption through organizational and technical measures and to improve energy-related performance in the longer term. [WIKIPEDIA ISO 50001]

Integration ProVis.NT

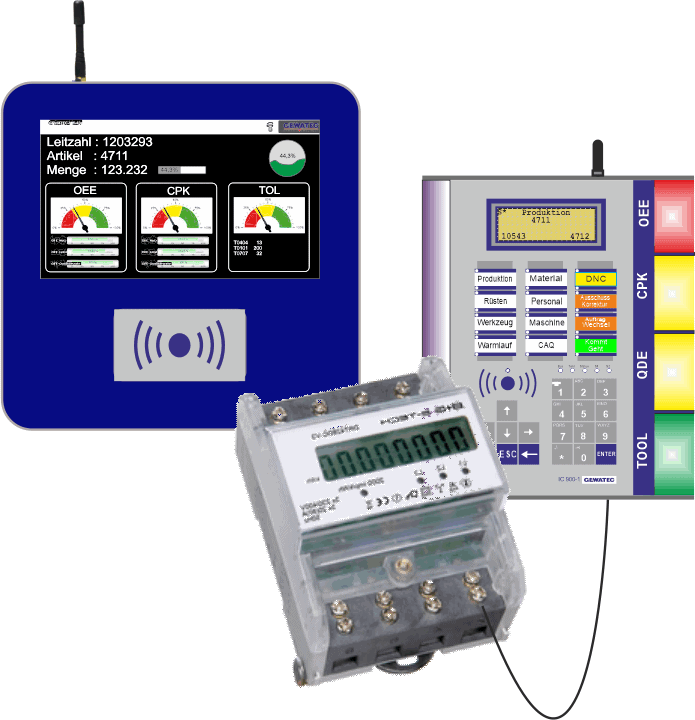

GEWATEC energy management uses the existing ProVis infrastructure. This saves costs and time. Older devices such as the IC901 can be upgraded to record energy data with little effort. Further advantages of the GEWATEC energy management system are:

- Use of existing ProVis infrastructure, easy retrofitting

- Compatible with existing MDE terminals, low effort for retrofitting MDE terminals

- Correlations between energy data and with machine data, production data, articles and orders from PPS and MDE/BDE

- Escalation management, notification services from ProVis

- Display of energy key figures at the MDE terminals and at the process traffic light

- Presentation of the energy consumption forecast in capacity planning

- Production control under consideration of current electricity prices

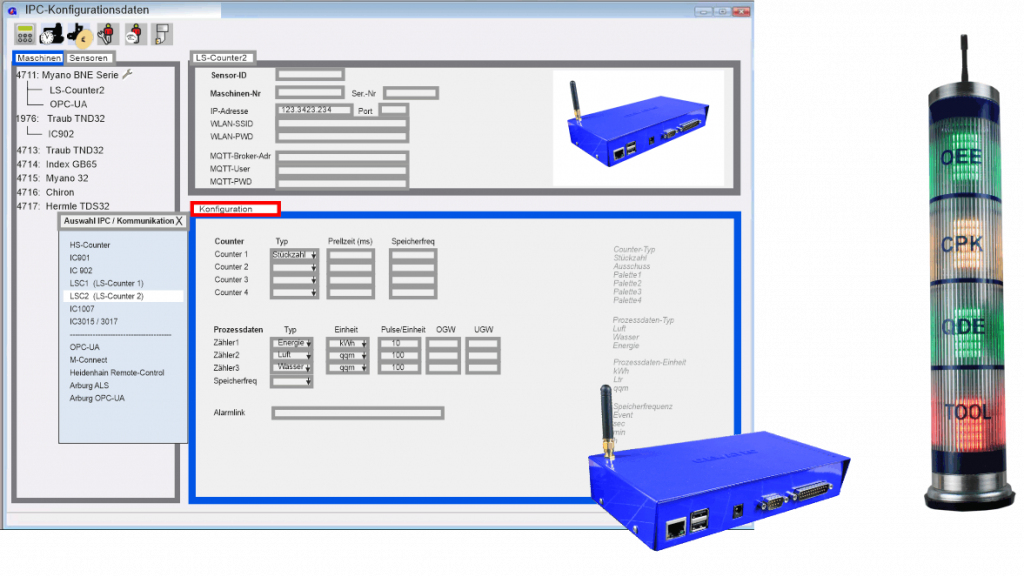

Sensor configuration

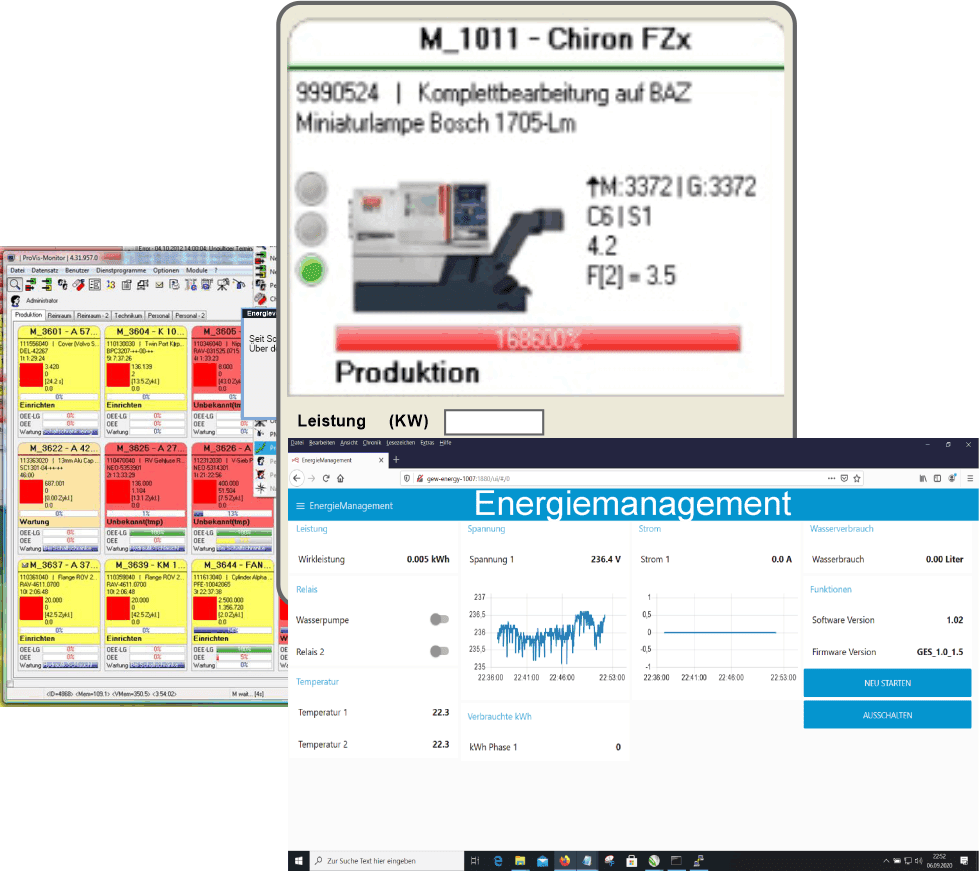

Various sensors are used to record process data. In addition to the use of meters, analog measured values such as pressure and temperature can also be recorded and processed. S0 meters are often used for the acquisition of energy data.

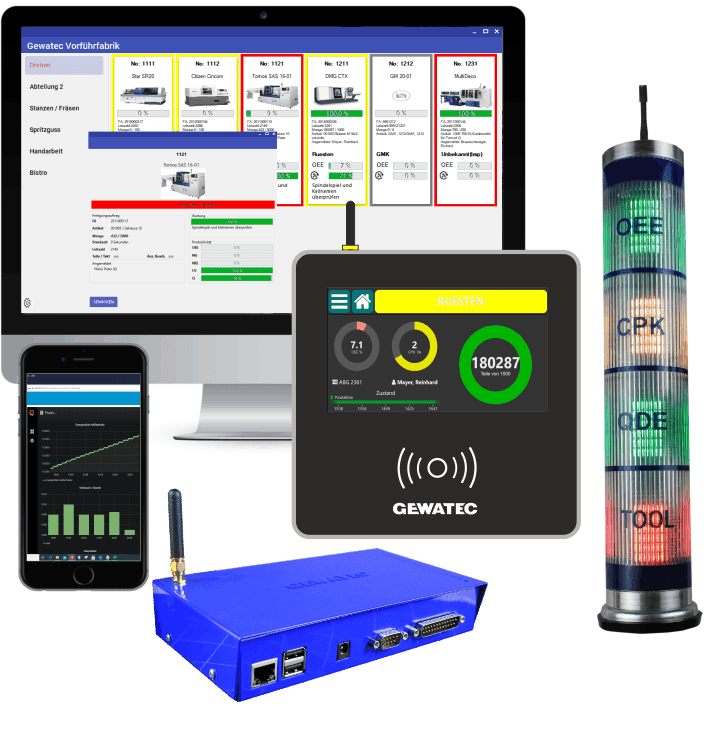

One or more sensors are assigned to each machine. The definitions of which sensor is assigned to which machine and which data it supplies are clearly defined in the ProVis sensor configurator. The sensors are cloud-enabled and deliver their data to a central database.

Energy sensors and actuators

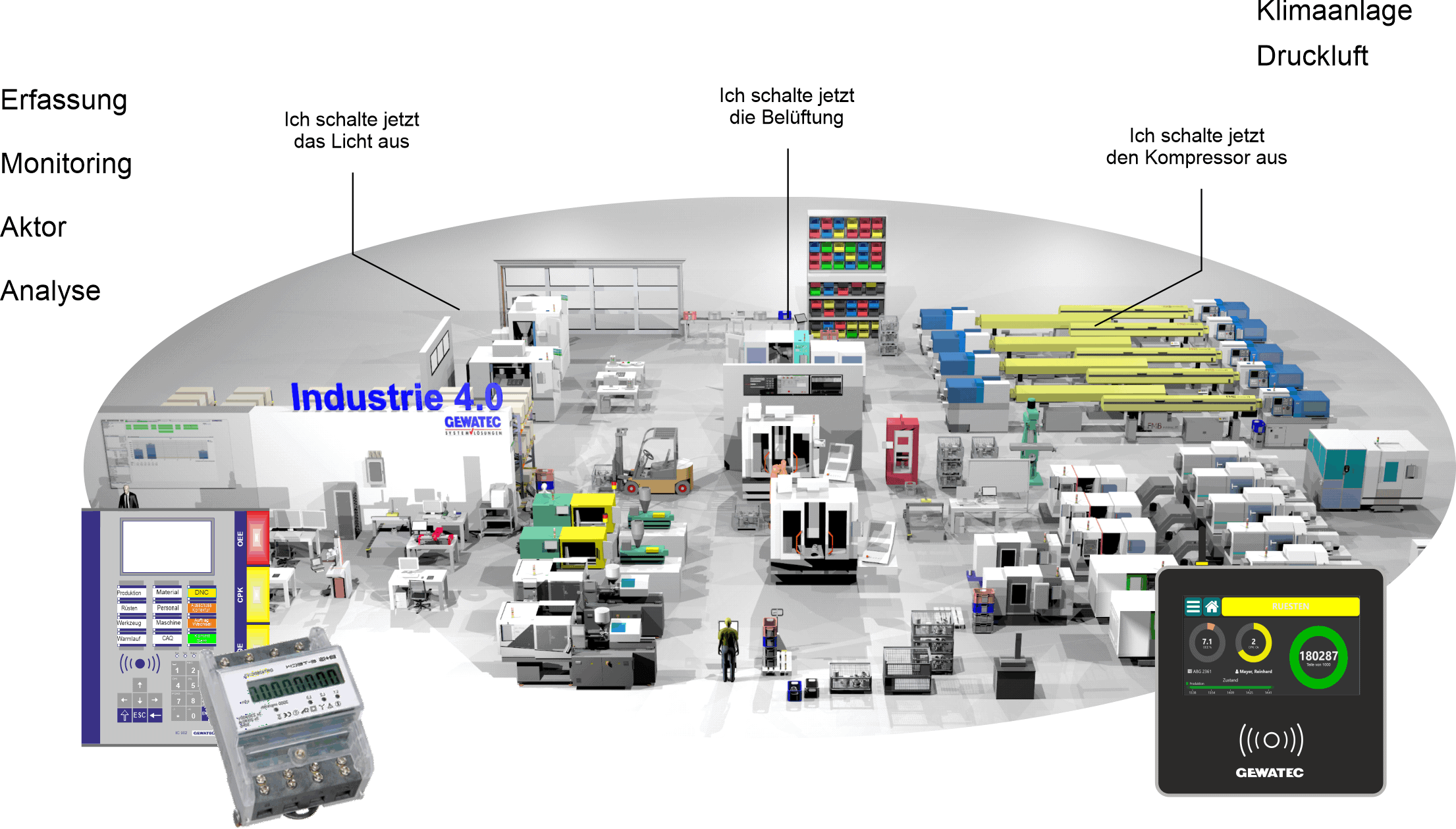

ProVis knows via the ProVis sensor the exact status (number of pieces, standing/running) of all machines in production (see ProVis scope of services). Many machines produce into the night shift until no more material is available. With the ProVis energy controller of the ProVis energy management it is possible to switch compressors, lighting, air conditioning and other consumers on and off, if various machines or machine groups are no longer producing. A freely definable event script enables the user to switch any consumer on and off.

In addition to switching consumers, any and freely programmable messages can also be sent via email or SMS.

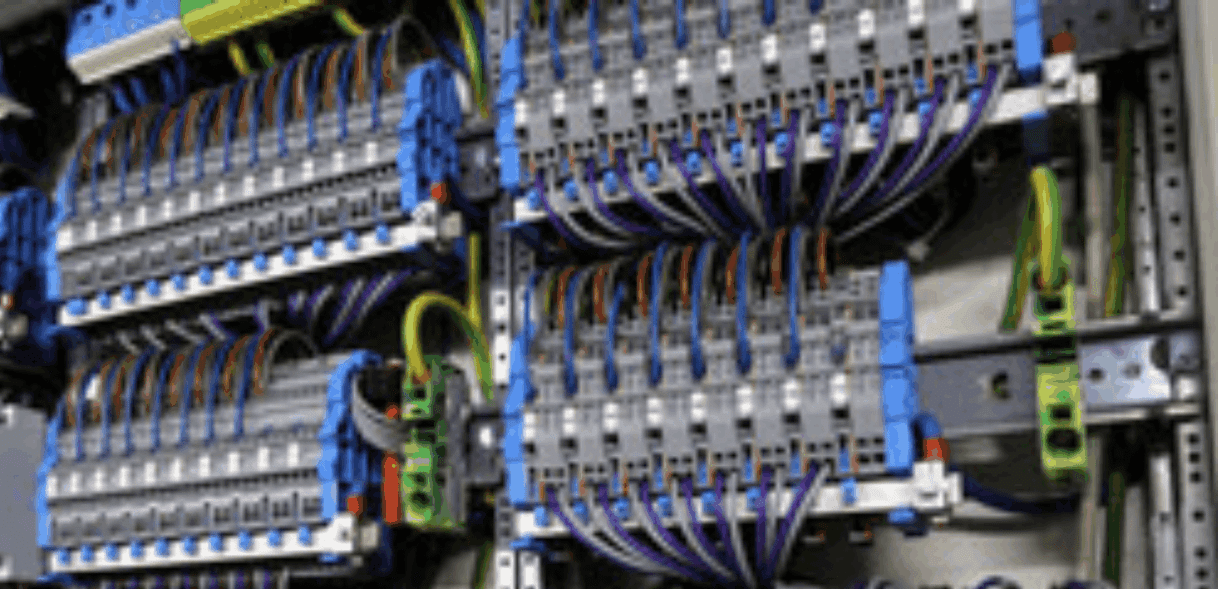

The ProVis consumption meter is installed in the control cabinet of the machine. The currents are recorded over all 3 phases. The ProVis consumption meter is connected directly to the corresponding ProVis sensors. In addition to the recording of electrical consumers, the consumption of air, water and gas can be determined via corresponding sensors.

The ProVis consumption meter is installed in the control cabinet of the machine. The currents are recorded over all 3 phases. The ProVis consumption meter is connected directly to the corresponding ProVis sensors. In addition to the recording of electrical consumers, the consumption of air, water and gas can be determined via corresponding sensors. | 8 analog inputs are available for recording temperature and pressure. Thus, sensors with analog output can be integrated into the ProVis system. The process data obtained via the sensors are stored in the ProVis process database. |

|

To measure the air consumption, a sensor for air volume measurement is installed in the air supply of the machine. Via an S0 interface or any digital signals (TTL signals), the IC901 can record the air consumption. The consumption values are stored analog to the process data in the ProVis SQL database. |

|

ProVis-NT now records climate parameters such as temperature, humidity and CO2 values. Any number of CO2 sensors can report their values to the ProVis control station via WLAN. The CO2 content as well as limit violations can be displayed via the ProVis process traffic light. An overview of all CO2 sensors is visualized on the ProVis control station. All climate data (CO2, temperature and humidity) can be read via the ProVis web monitor on the IPhone. |

Energy Monitor

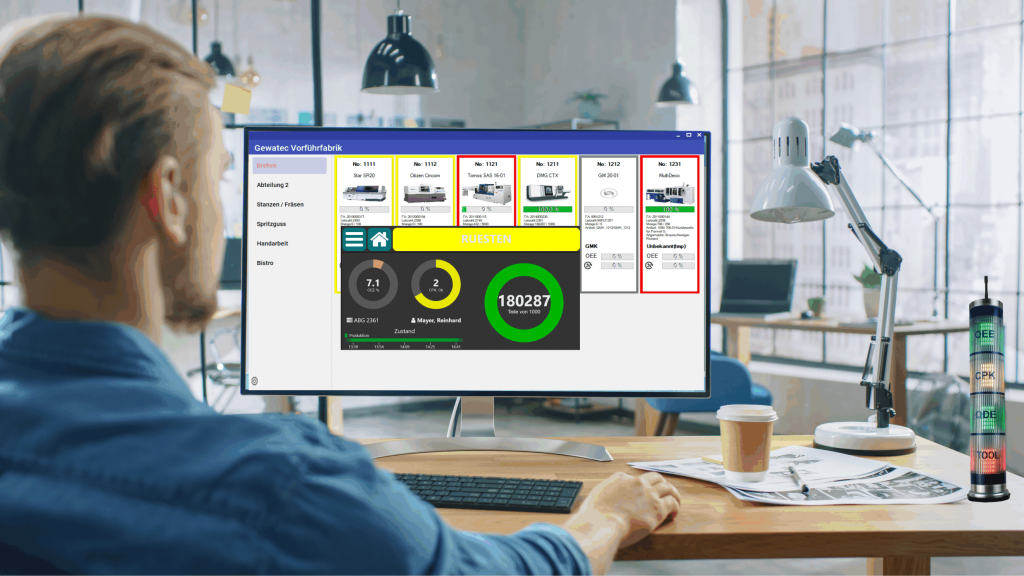

ProVis energy monitoring visualizes the energy consumption of your production resources. Via the ProVis sensors, the consumptions are reported directly to the control station. The consumption values are archived and visualized in the same way as the process data. The energy consumptions recorded in this way can later be assigned to machines, shifts, tools, materials and articles. GEWATEC post-calculation determines the energy consumption per production order and article.

Evaluation / Analysis

In addition to energy monitoring at the ProVis control station, an analysis of the consumption data with Business Intelligence (BI) is possible. Here, correlations of the energy data with the production data from the PPS system are established.

- Visualization of the energy consumption

- Energy consumption per shift

- Energy consumption per machine

- Energy consumption per item

- Energy consumption per production order

- Visualization of the data on the iPhone, on the desktop or on the MDE terminal