Production equipment management, Maintenance and repair

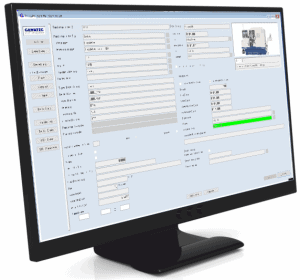

Production equipment and its components and spare parts are managed and monitored in the GEWATEC Production Equipment Management System PMS. This allows maintenance plans with different due dates to be assigned to the individual production resources and processed.

Intelligent parts list logic allows components and maintenance plans to be assigned as required. The indication of damage patterns during planned and unplanned maintenance provides information about the current condition and the operational capability of the individual production equipment.

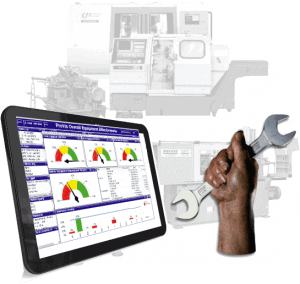

The functional safety and reliability of complex equipment and production resources, and thus their availability, can be maintained at a consistently high level of productivity with a consistent preventive maintenance concept.

Therefore,the demands on modern production resource management are cost reduction, higher efficiency and increased availability of machines and spare parts. Systematic weak point analysis and prevention are also of central importance. Therefore, the required maintenance measures are harmoniously integrated into the production process with PMS from GEWATEC.

PMS Highlights

- Management of production equipment, spare parts and stock

- Parts lists

- Maintenance plans

- Maintenance and inspection history

- Cost recording

- Deadline monitoring according to time or wear