Technical and commercial calculation

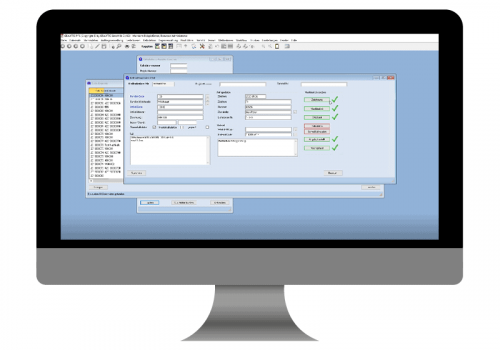

Fierce competition and high cost pressure are forcing manufacturing companies to use rational and transparent costing. The overhead calculation is based on a detailed machine hourly rate calculation. Recording costs at the point where they are incurred provides an ideal basis for costing. For example, all machine-dependent costs can be considered separately, since they can be excluded from the manufacturing overhead costs.

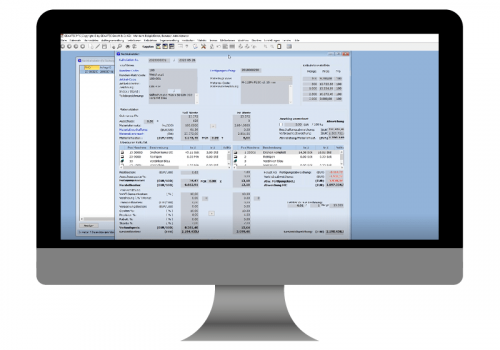

GEWATEC offers you effective tools for the realization of multiple calculation models. This puts you a decisive step ahead of the competition. In addition to the modules mentioned, the software also contains the accompanying costing, the post-calculation and the assembly costing.

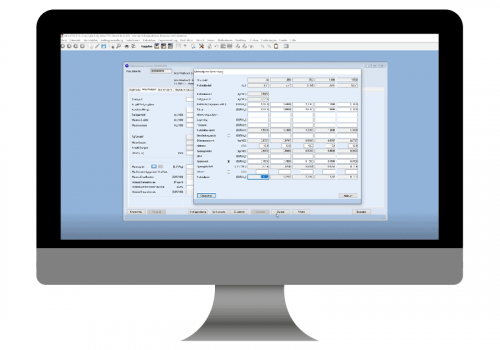

Piece time calculation

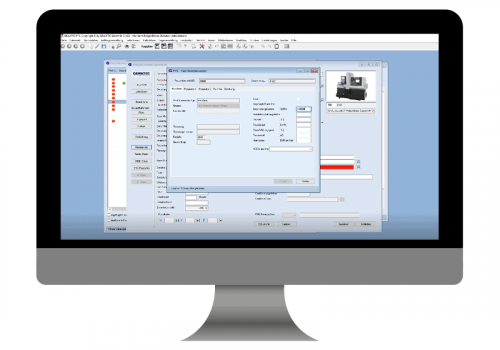

Machine hour rate

With the software module machine hourly rate, cost rates for all machines or workstations used are calculated in detail and quickly. Included are the hourly rate calculation for shift models taking into account the annual planned duration, depreciation, space costs and maintenance. Within the shift models, a distinction is made between wage cost rates for setters and operators. With modern BI tools, there are numerous evaluation options.

Quotation costing

The quotation costing is a classic overhead costing, which is divided into tabs for optimal orientation. In the tabs you will find, for example, the material cost calculation with the help of volume and weight calculations. An assembly costing is also integrated, which links articles or further sub-costings. The sequence of work to be calculated is divided into internal and external production costs, in which the machine hourly rate calculation is decisive. Based on the machine utilization, an investment cost calculation can be displayed. In the results tab, the full cost and marginal cost calculation is displayed, taking into account transport and packaging costs. With the module quotation calculation a quotation tracing is possible.

.

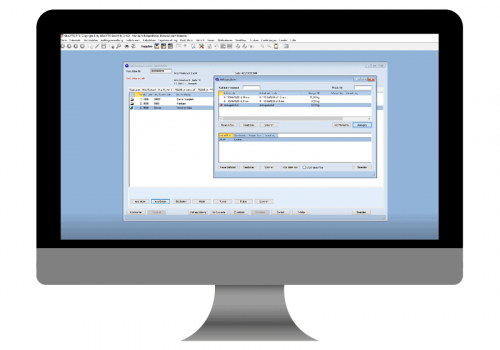

It is important for cost-optimized production that the processed production orders can be recalculated with little effort.

This is possible with minimal effort in connection with the GEWATEC MDE/BDE system ProVis. All relevant data is recorded during production. You receive detailed information on the actual piece times, set-up times, manufactured piece numbers, scrap, material consumption and utilization levels. Deviations between target and actual are clearly displayed.