The PPS system for series manufacturers, automotive suppliers, plastic injection moulders and medical technicians

The GEWATEC PPS system was developed for medium-sized manufacturing companies in the precision parts production, series production and medical technology sectors. In combination with the offer calculation WIN-KALK, the Quality control GRIPS and the machine and production recording solution ProVis, a modern, powerful solution with unique selling points has been created.

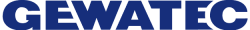

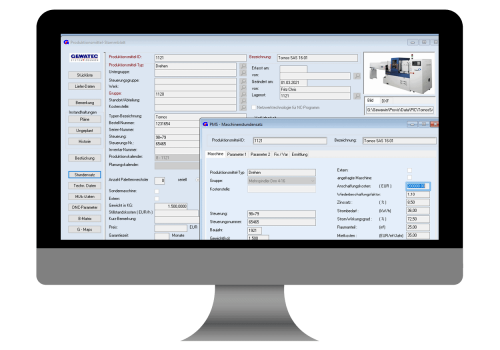

Calculation

Fierce competition and high cost pressure are forcing manufacturing companies to use rational and transparent costing. The overhead calculation is based on a detailed machine hourly rate calculation. Recording costs at the place where they are incurred provides an ideal basis for calculation. For example, all machine-dependent costs can be considered separately, as they can be excluded from the manufacturing overhead costs.

GEWATEC offers you effective tools for the realisation of several costing models. This puts you a decisive step ahead of the competition. In addition to the modules mentioned, the software also contains the accompanying calculation, the post-calculation and the parts list calculation.

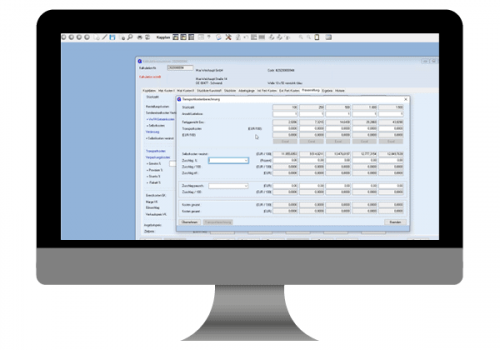

Purchase

The ordering module is used to perform the entire ordering process efficiently, especially for purchased parts, raw materials and tools. Suppliers and articles can be accessed via the master data to create the ordering process. Furthermore, different order types such as individual or on-call orders can be selected. To complete the order process, one of the many delivery conditions can be selected. Via the goods receipt, the order is discharged and the supplier evaluation is triggered. Open orders can be viewed and monitored using the order statistics.

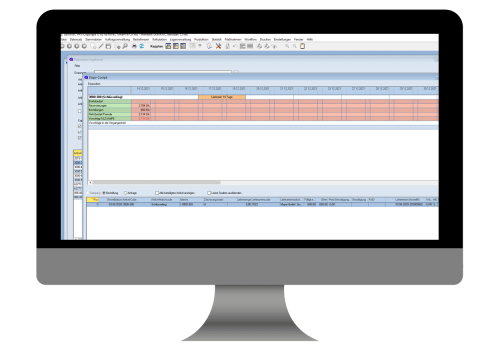

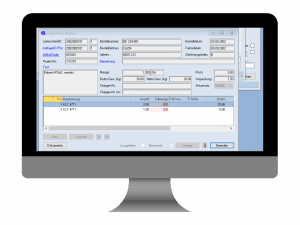

Order management

You create offers to customers and interested parties in the offer management. When creating customer orders in order management, a distinction is already made between on-call orders and individual orders. With the creation of orders, confirmations can be sent automatically to the customer. The creation of delivery notes relieves the job. These in turn serve as the basis for invoices. The GEWATEC statistics module provides an overview of invoice journals as well as stock overviews and sales statistics.

Set management for medical technicians

Set management is particularly practical for the trade and medical technology sectors. Orders in these sectors must be created and managed quickly, reliably and with any number of positions. In contrast to the order-item logic, the generation of orders takes place in a table. In a simple way, items can be moved by drag-and-drop. Exchange and repair of sets are handled in the “repair management” module.

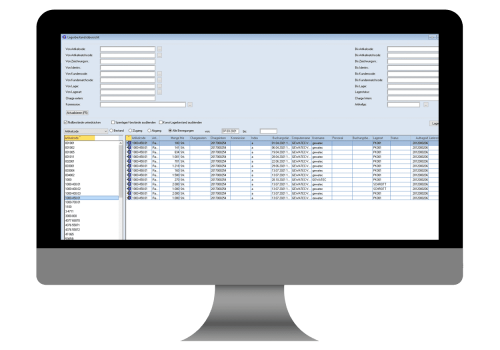

Warehouse management

A prerequisite for efficient and meaningful warehouse management is the complete recording of warehouse movements. Stock movements are recorded via terminals and smart devices. The software for warehouse management offers the possibility to make additions, deductions and transfers. Any number of storage locations can be created. As a result, stock, inventory and valuation lists can be created. In connection with ProVis, a valuation of semi-finished parts can be carried out.

Further features:

- Graphical storage location display

- Assembly bookings

Tool management

If storage and retrieval systems have digital interfaces, they can be integrated into GPPS. Tool dispensing systems often have such interfaces. GPPS supports a variety of interfaces to tooling and racking systems. The most important functions include master data as well as stock reconciliation, stock management and the write-back of automatic stock postings. Withdrawals are carried out according to the specifications of the production order. Order proposals are processed on the basis of the MRP.

All the functions described are dependent on the output system.

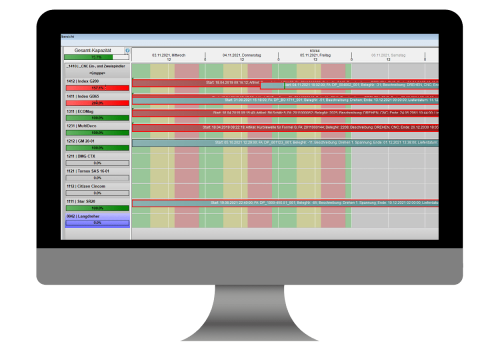

Disposition

The task of scheduling is to distribute orders, material flows and stocks of goods in a timely manner. The required goods are ordered on the basis of the planning result. A distinction is made between demand-driven and consumption-driven scheduling. The user is presented with order and production proposals. Shortages are shown in a gross and net requirements calculation.

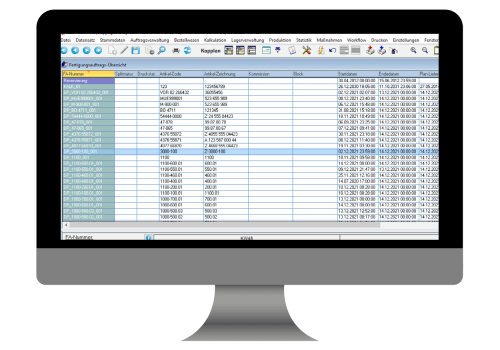

KapPlan is a convenient control centre system for planning the utilisation of the production resources machine and personnel. With KapPlan, the occupancy and utilisation of all machines, workplaces and departments are displayed in a clear form. All operations of the production orders are displayed over the time axis, taking the calendar into account.

With KapPlan you have full control of your production capacities. The graphical planning board makes it easy to move operations by “drag & drop”. Comparable to an early warning system, capacity bottlenecks are displayed immediately. Free capacities can be optimally utilised. Zoom functions enable the setting of any time window. Work processes can be shifted across different workplaces and departments.

Financial accounting interface

GPPS offers a variety of interfaces to all common financial accounting systems. Our most important interfaces include Datev, Navision, Addison, eGecko and many more.

With the import of incoming payments from the financial system, a dunning system can be set up as a by-product.

DFÜ/EDI

EDI is a standardised procedure for the electronic exchange of business data between customers and suppliers. For example, delivery schedules or JIT delivery schedules are sent from your customer to you. Conversely, you can send delivery note and invoice data to your customer.

Support of all relevant VDA standards :

- Goods tag (VDA4902)

- Goods accompanying note (VDA4912)

- RDT delivery note (VDA4913)

- RDT invoice (VDA4906)

- Delivery call-off (VDA4905)

- Purchasing (VDA4905)

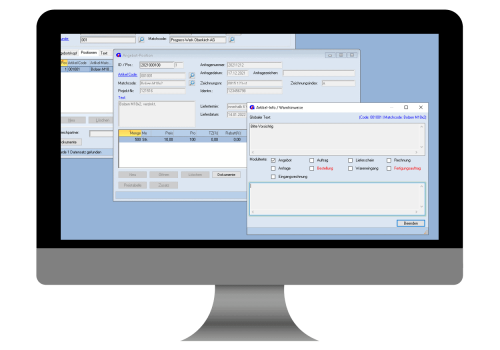

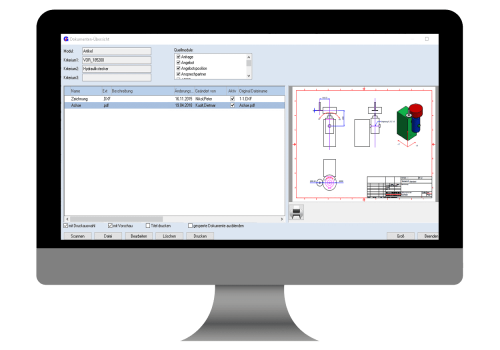

Document management (DMS)

This module is used to manage any documents. In addition to digital documents, scanned documents can also be attached and managed. Documents can be stored for all master data and business processes. Documents can be copied to any module via intelligent distribution strategies.

Delivery

The user is guided through the process via various dispatch strategies for creating delivery notes. Quantities can be transferred directly to the delivery note via connected scales. Goods tags and labels are created and printed out at the touch of a button. Each delivery note created is compared with its order delivery schedule. The packaging material management ensures the correct booking of used customer packaging materials.