GEWATEC CAQ

GRIPS is a modern quality management system that meets all the requirements of the automotive supply industry and medical technology. With GRIPS, you always have the quality of your products firmly under control and fulfil all requirements of the VDA, ISO, QS9000 and TS16949 standards and the FDA. GRIPS is a comprehensive product and process-oriented quality management system for monitoring and controlling your production. The integration of further QM modules enables efficient work in the areas of quality management.

EMP (Initial Sample Inspection)

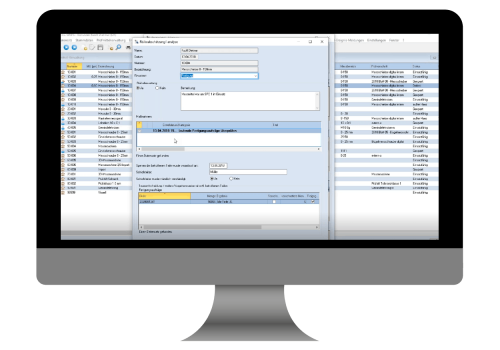

With the creation of the initial sample inspection report, the supplier provides proof that its products meet the quality requirements demanded by the customer. The release procedures according to the current standards and specifications include both product and -process release. The QDX interface enables the digital data exchange of initial sample inspection reports via SupplyOn.

You have the option of processing the initial sample inspection reports in GRIPS-EMP both as a supplier and as a customer. The processes for creating initial sample inspection reports are constantly adapted to the current standards (VDA 5th & 6th edition, QS9000/ PPAP, IATF 16949).

QDX: Data interface

Since 01.09.2014, BOSCH has made it possible to electronically process the entire initial sample inspection report process worldwide using the BOSCH web portal via SupplyOn. In cooperation with BOSCH, we have developed a BOSCH QDX convenience interface, which you can use to comfortably exchange your initial sample reports.

The entire sampling process is supported with the following functions:

Import BOSCH EMPB target report

Export of your EMPB actual report

Import of the BOSCH decision

Nest sampling

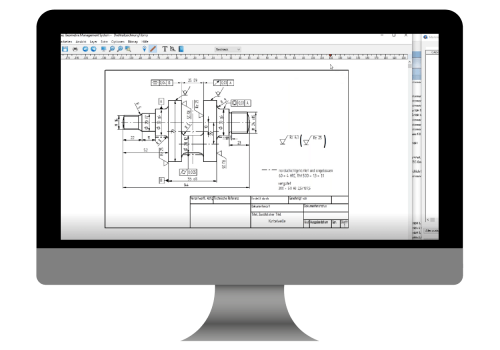

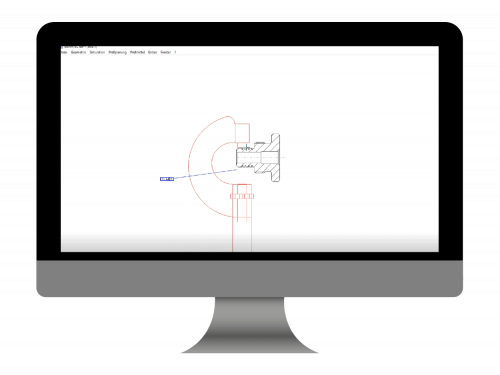

EMP Stempelsoftware, die grafisch interaktive Erstbemusterung

The integrated marking software supports you with the efficient marking of the drawings as well as the automatic generation of the inspection characteristics from the drawing. Dimension and tolerance values as well as marking numbers and feature positions are imported directly from the drawing.

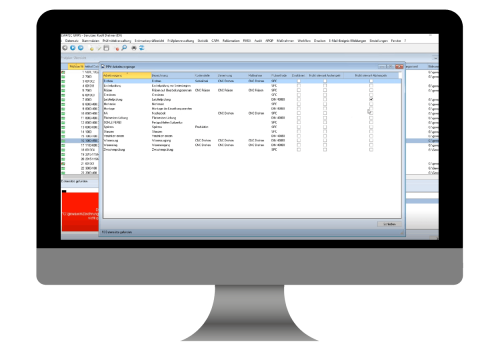

PMV (test equipment management)

Quality control requires that the test equipment used is subjected to constant monitoring and calibration. In the GRIPS test equipment management system, all test equipment is recorded in accordance with standards and managed rationally. The constant monitoring of test defects as well as the monitoring of the place of use are integrated into the GRIPS test equipment management as standard. The test equipment can be assigned to specific persons or workplaces via the test equipment movement. In addition, connections to different tool cabinets are obligatory. Test equipment capability tests according to the various MSA procedures are optional.

PMÜ (test equipment monitoring)

Calibrations can be carried out via the GRIPS- PMÜ on the basis of generally valid calibration plans according to VDI/ VDE / DGQ 2618 or individually adapted calibration plans. The monitoring history allows the evaluation of test equipment-specific calibration and usage data as well as:

- Status history

- Cost recording and evaluation

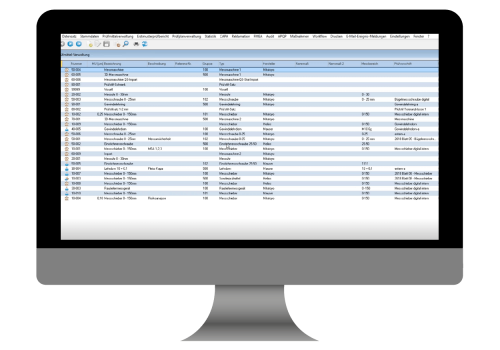

PPV inspection plan management

In the GRIPS inspection plan management, the inspection plans are created with the respective operations and the associated characteristics. The user is guided quickly and efficiently through the creation of the inspection plans via context-related menus. The creation of standardised forms, e.g. a control plan, is included in the scope of the standard software. The simple designation as a family inspection plan allows the transfer of all or individual characteristics. The linking of the characteristics in the inspection plans is easily visible. Changes to a family characteristic are transferred to all linked characteristics.

GRIPS inspection planning includes the creation of in-process inspection plans (SPC) as well as goods-in and goods-out inspection plans of different inspection severities and methods. The additional module GIP (graphical interactive inspection planning) supports the worker by visualising individual measuring steps. One of the unique selling points of the GEWATEC solution is the optional linking of GRIPS and PROVIS. For example, inspection orders can be automatically generated during the registration of production orders in production. The nest-related measurement data acquisition used especially in plastic injection moulding is also possible in the standard software.

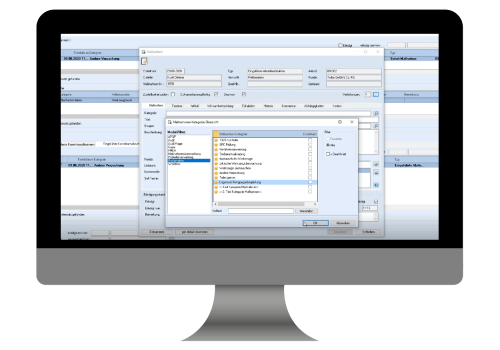

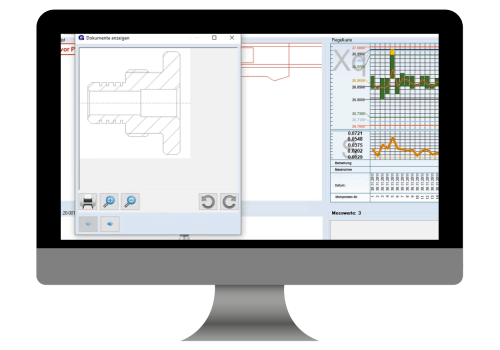

QDE Quality data recording

Independent of the inspection equipment connected to the GEWATEC software, the operator is guided through the measuring process via graphically interactive dialogues. The control chart embedded in the measuring process visualises the process sequence of the corresponding characteristic. The characteristic to be inspected and the test equipment to be used are displayed in the open measuring window. Any tolerance violations are marked in colour. Remarks and measures can be recorded in the control chart and provide information about process changes and their causes. The integrated nest management navigates the worker through the measuring task for plastic injection moulded parts.

Other interesting features include the monitoring of inspection intervals and the connection of a wide range of inspection equipment (hand-held measuring equipment, measuring machines, etc.).

QSTAT: Qualitätsstatistik Kontinuierliche Verteilungen:

| Numerische Testverfahren: |

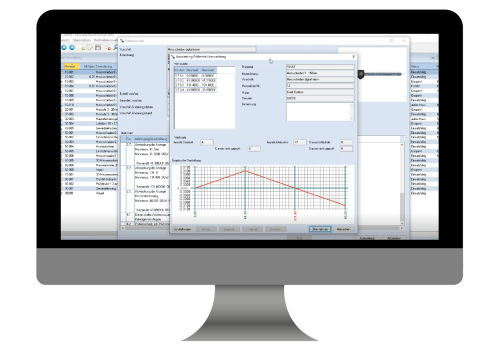

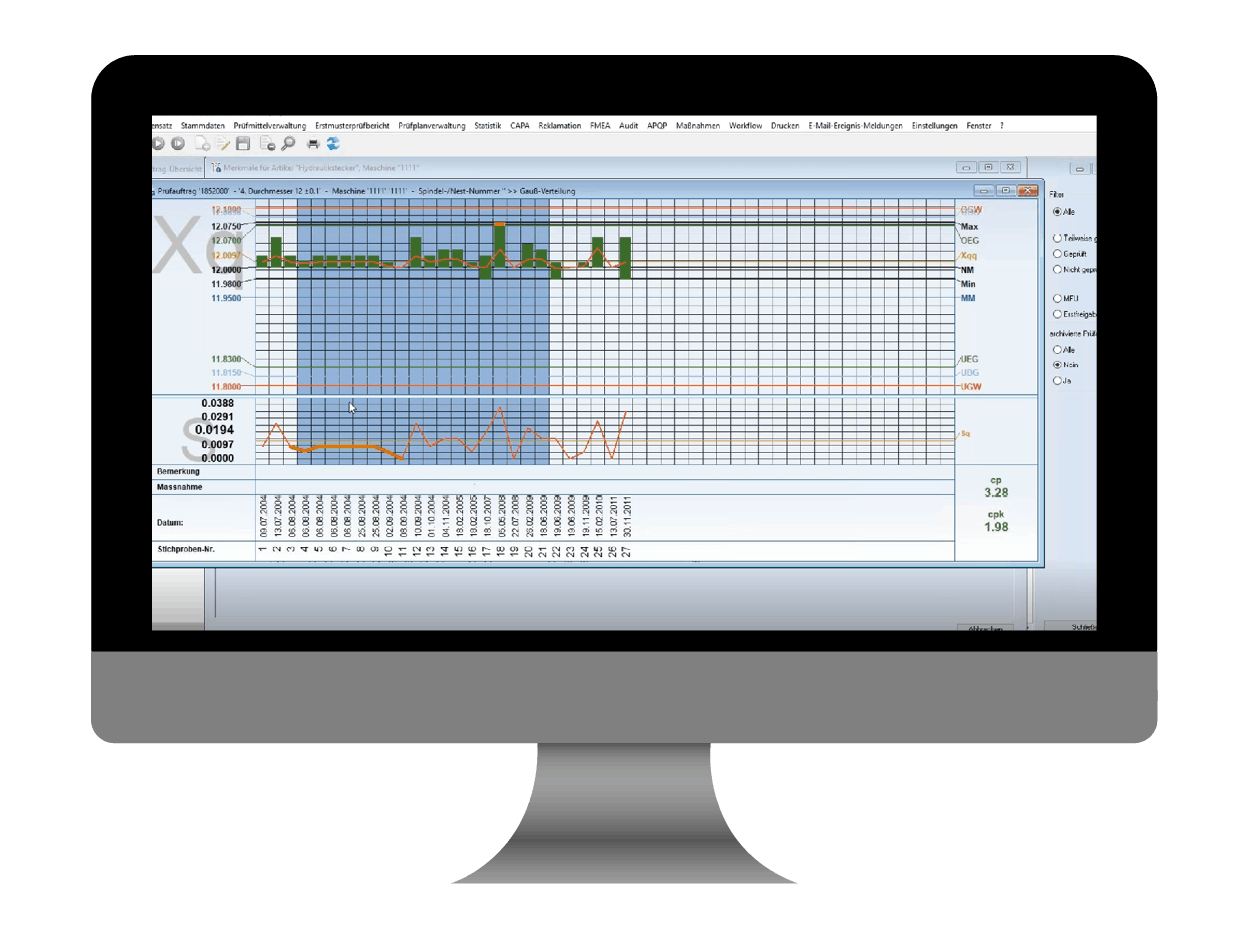

QST evaluation, statistics

In the QST module, measured values recorded in advance can be statistically evaluated in different procedures. The evaluation is carried out directly on the corresponding characteristic-related control chart. The calculated key figures provide information about the stability and process capability of the respective process characteristic. In addition to the process capability analysis (cp/ cpk), the user can also perform machine capability analyses (cm/ cmk). The creation of measurement reports after the incoming and outgoing goods inspection requires only a few clicks. Original value lists can be called up directly from the control chart as well as via individually adapted reports. The evaluation of the measured values in different control charts (Xquer/ S/ R) as well as different distribution types allows a high degree of flexibility in the quality assessment. Short evaluations allow a quick overview of the most important statistical parameters. When evaluating SPC inspection orders, it is possible to recalculate intervention limits on the basis of the process progression and to visualise the processes in different forms of representation (control charts/histograms/ probability network). The following additional information is integrated in the standard software:

- cpk/cmk warnings

- Message in case the test values are exceeded

REKLA complaints processing

In GEWATEC complaints processing, external supplier and customer complaints as well as internal complaints can be recorded and managed. Customer complaints are processed and documented according to structured standards from the automotive industry, the 8D method or the 5W method. Supplier complaints as well as internal complaints are described in detail in a test report and sent to the corresponding person in charge. The printing of blocking cards allows the visual identification of goods that are the subject of a complaint. All complaint-related cost types are recorded in the respective complaint, added up and thus form the basis of detailed cost evaluation. The measures created in the complaint are reported to the respective person responsible via the central measures management and monitored. Direct access from the complaint to the stock and production overview of the respective item in GPPS enables a quick overview. Complaints from customers can be forwarded directly to the supplier if necessary. Comprehensive evaluations support the user in analysing a wide range of criteria.

- Request for one-off construction deviation

- Complaint proposal directly from the measuring station

- Rekla web client

- Ishikawa

FMEA

The GEWATEC FMEA module can be used to create both process and product FMEAs based on knowledge. The possibility of linking basic FMEAs with item-specific FMEAs enables fast and efficient risk assessment and evaluation. Changes can be easily inherited from the basic FMEAs to the item-specific FMEAs. A clearly defined explorer structure guides the user step-by-step through the creation of the FMEA. If necessary, it is possible to switch to the view of the VDA form. Both the evaluation according to RPN and the evaluation according to task priority (AIAG VDA 2019) are integrated as standard. In addition to already stored evaluation catalogues, it is also possible to use individually created evaluation catalogues. The transfer of functions directly from inspection planning as well as the direct data transfer from complaint processing allow a consistent risk assessment. The blocks of measures derived from this are managed and monitored in the central measures management.

LBEW (supplier assessment)

In the GRIPS LBEW, suppliers are evaluated according to product quality, delivery reliability and delivery quantity. The corresponding quality score is calculated on the basis of the selection made. The evaluation can be performed for specific articles as well as for all articles.

Audit/ -management

GRIPS Audit Management is used to perform internal and external audits. In addition to the standard-specific audit catalogues, it is also possible to create individual catalogues. By selecting the catalogues to be used, the corresponding audit plan is generated for the respective audit. The definition of the standard-specific evaluation criteria allows audits to be performed in conformity with the standard. Questions that are not 100% fulfilled force the user to formulate appropriate measures. These measures are managed and monitored in the central measures management. The calculation of the evaluation number visualises the current degree of fulfilment of the audit.

APQP

“Advanced Product Quality Planning” is based on the former QS 9000 and is a project management tool for product and quality planning. For some time now, APQP has been a central module in the catalogue of requirements of IATF 16949 in the area of advance quality planning.

The aim is to avoid errors by means of a uniform, product-related documentation structure/hierarchy, which provides the user with the necessary

transparency of the manufacturing process. This should simplify production control

be simplified. All project- and product-relevant information and documents are

are centrally planned, monitored and managed. All resulting tasks, deadlines and measures are transferred to the GEWATEC measure management for further processing and tracking.

Necessary corrections and adjustments to deadlines and tasks are possible by simply moving the “tasks” in the Gantt chart.

Messrechner, Messmittelinterface, Messmittelmultiplexer

The GEWATEC IC3015/17 can be transformed into a compact measuring station. Measuring computer and multiplexer for Mitutoyo Digimatic, Opto-RS232 are completely integrated. Measuring probes, for example from Heidenhain or Sylvac, can be easily connected to the GEWATEC measuring station. Measuring machines of all common manufacturers can usually be connected to the GEWATEC data acquisition via file sharing.

- 8 x Mitutoyo Digimatic interface integrated .

See also GEWATEC Industrial Computer (IPC)